-

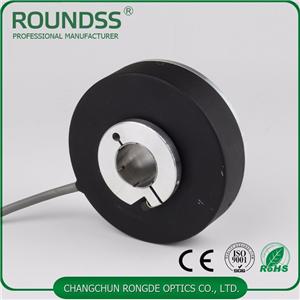

Rotary Encoder Incremental Encoder Sensor

Rotary encoder is the sensor which could convert the shaft mechanical displacement to digital or pulse signals. On the incremental encoder disc, there are many square holes equally spaced. The rotary encoder could output the pulse signal through the electrical part reading the holes on disc.

-

Multi-Turn Absolute Encoder Rotary encoder

Best Price 12 Bit SSI Multi-Turn Absolute Encoder Rotary encoder:Absolute rotary encoders divide into single-turn absolute encoder and multi-turn absolute encoder. The code track is designed by using Gray code, matrix code, cursor code, pseudo-random code, etc. When the shaft rotates, there is a code output corresponding to the position. From the change in code size, the position of the forward and backward directions and the displacement can be distinguish without direction judgment circuit. It has an absolute zero code. When power is outage or turned off, when it is turned on and re-measured, the code of the power outage or shut down position can still be accurately read, and the zero code can be accurately found. ROUNDSS Absolute rotary encoder provide multiple interfaces:RS485, RS422, RS232, SSI, MODBUS, Canopen, parallel or analogue. The sensor has multiple shaft diameters are optional.

-

Manual Pulse Generator Manual Control Pendant

Manual Pulse Generator is an optical rotary encoder designed for manual input of pulses to CNC machine tools. It is mainly used for instruction type CNC machine tools. CNC machine work origin setting, manual step fine adjustment, interrupt insertion during machining, etc. The band switch is used for the selection of the axis and the override, and the encoder is used for the pulse to facilitate the acquisition of the system. It is classified according to the supply voltage, resolution, and signal output type, thus forming a manual pendant suitable for various types of CNC control systems.